- You do not have any products in your shopping cart yet.

When passion becomes responsibility.

We have been experts in the sector for over 8 years. The idea of perfect wheels does not remain a dream for us. We are constantly creating and developing new solutions in Germany.

Innovative and strictly monitored production cycles are part of our daily routine and guarantee a high level of safety beyond the TÜV standards.

What do we do that the others don't? We take the precision of our wheels very seriously - every vehicle in our target group gets a tailor-made solution to get the most of the look without being forced to use spacers or to modify the fenders.

Many competitors rely on references and manufacture according to comparative dimensions. These are universal solutions from which we clearly distance ourselves. We analyze, measure and test the aimed vehicle in detail in order to develop the best wheel for the requirements. Only then we can speak of a custom-made and high-performance rim. Every Flowforged and Forged rim from our company not only enhances the vehicle look but also guarantees a performance and driving comfort that is second to none.

HOW ARE OUR WHEELS MADE?

The WF brand stands for innovation and German engineering.

Our production technologies are strictly monitored and constantly tested by TÜV Rheinland.

Our factory produces all FLOWFORGED (short: FF) wheels

with this advanced process and achieves an outstanding quality.

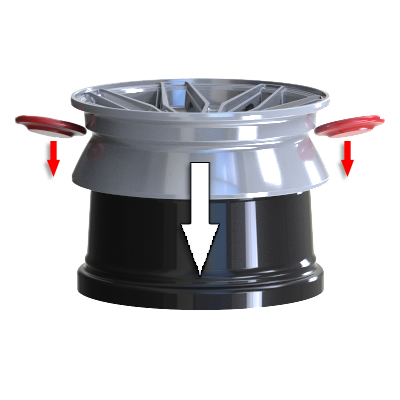

STEP 1

After the production of the Flowforged blank, it is placed on a roller mould and heated extremely.

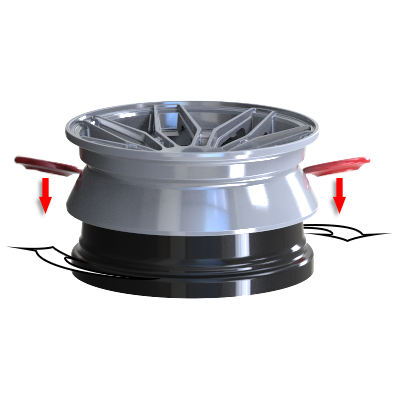

STEP 2

Special hydraulic rollers tension the wheel by applying pressure to the barrel, while targeted heat is applied as the rotating barrel.

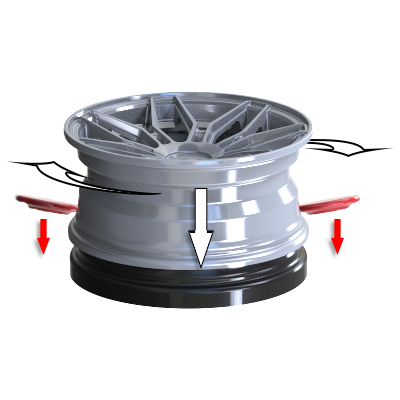

STEP 3

By rotating precisely, the rollers form the blank into the desired wheel width. The material is made extremely strong and resilient through compression.

STEP 4

Once the high-strength blank is in its final shape, the wheel is taken to the CNC department for milling and turning.

CHECK WF STUFF.

Follow us on Youtube!

When passion becomes responsibility.

We have been experts in the sector for over 8 years. The idea of perfect wheels does not remain a dream for us. We are constantly creating and developing new solutions in Germany.

Innovative and strictly monitored production cycles are part of our daily routine and guarantee a high level of safety beyond the TÜV standards.

What do we do that the others don't? We take the precision of our wheels very seriously - every vehicle in our target group gets a tailor-made solution to get the most of the look without being forced to use spacers or to modify the fenders.

Many competitors rely on references and manufacture according to comparative dimensions. These are universal solutions from which we clearly distance ourselves. We analyze, measure and test the aimed vehicle in detail in order to develop the best wheel for the requirements. Only then we can speak of a custom-made and high-performance rim. Every Flowforged and Forged rim from our company not only enhances the vehicle look but also guarantees a performance and driving comfort that is second to none.

.png)